Many Health Authorities worldwide recognise the critical nature of a Sterile Barrier System.

What exactly is a Sterile Barrier System (SBS) ?

Tyvek Seal and Polyurethane Packaging form the Sterile Barrier System in this Picture

This is the external barrier (some examples can be Tyvek material or Polyurethane seal) which separates the internal components, powders, medicines etc from the elements. Hence it is crucial that the sterile barrier is never compromised.

A key function of a sterile barrier system is to maintain the safety of a terminally sterilised medical device until its point of use - typically in a healthcare setting.

QRA International network of Laboratories can evaluate the sterile integrity of your final packaging design through a series of seal integrity and seal strength testing outlined in ISO 11607 - Packaging for Terminally Sterilised Medical Devices.

Seal integrity testing identifies any leaks around the seal area of your packaging system.Seal integrity testing identifies any leaks around the seal area of your packaging system. Seal integrity testing is followed by seal strength testing to evaluate the mechanical strength of your packaging system and the force needed to separate and open the seal. A high numerical force value could indicate challenges in opening your packaging system by hand, and a low numerical force value could indicate poor bonding of materials.

Choose QRA International Medical Device Testing to help you to :

a) Validate your final packaging system

b) Monitor proper device performance during the manufacturing process.

c) Establish material compatability and proper bonding to maintain the sterile environment throughout the shelf life of your product.

d) Ensure the seal of your packaging system does not change due to environmental stressors such as distribution and shelf life.

Tests Available by QRA and its partners :

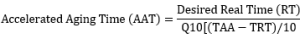

Accelerated Aging Tests

1. Accelerated Aging Tests (ASTM F 1980 - 21 and ISO 11607)

2. Shelf Life Test

Seal Integrity Tests

1. Visual Inspection (ASTM F1886)

2. Dye Penetration (ASTM F 1929 & F 3039)

3. Bubble Emission (ASTM F 2096)

Seal Strength Tests

1. Peel / Seal Strength Test (ASTM F 88, EN 868 - 5 Annex D).

Interested ? Contact the friendly QRA International Sales Specialists at

email : mark@qra.com.sg

qrasales@qra.com.sg

Or visit our website at www.qra.com.sg for more information

We are here to serve the International Biomedical Community